Esošais Sūknis - Cirkulācija

Nomaiņas sūknis - High Efficiency Premium Apmaiņats komplekts

Komentāri

Produkta informācija

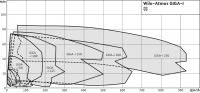

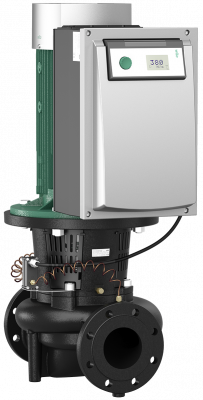

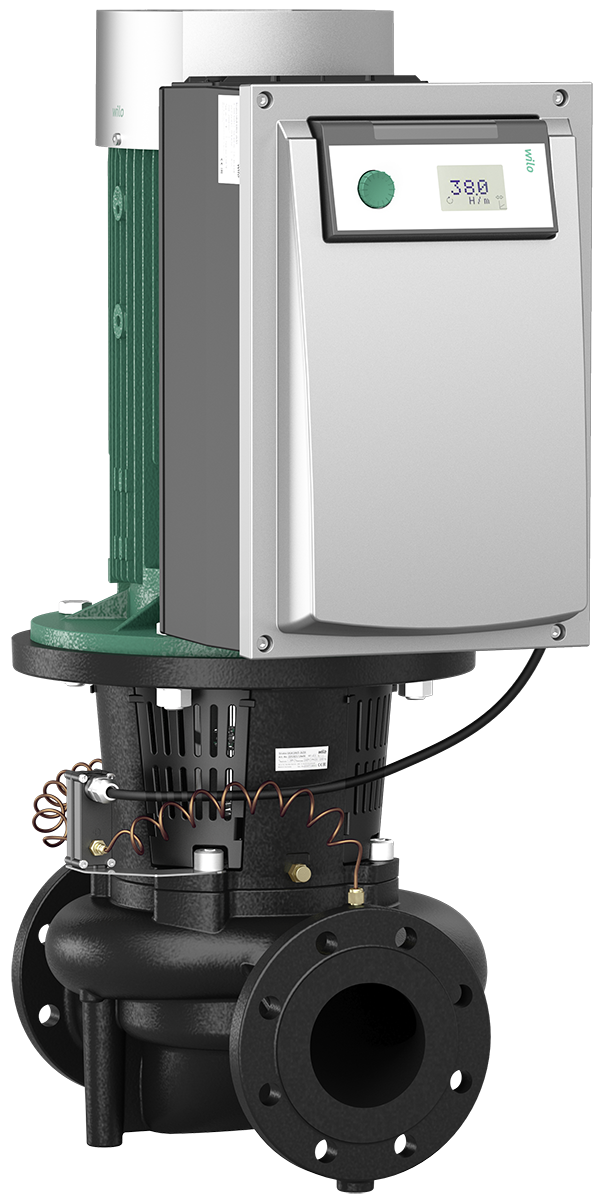

Stratos GIGA 100/2-29/15

Your advantages

- Innovative high-efficiency pump for maximum overall efficiency levels

- High-efficiency EC motor with efficiency class IE5 according to IEC 60034-30-2

- Highest possible operational reliability thanks to standby pump

- Optional interfaces for connection to building automation using insertable IF modules

The Wilo-Stratos GIGA is the ideal high-efficiency pump for use in heating, air conditioning and cooling applications in buildings where large volumes of water have to be pumped to great delivery heights. Wilo-Stratos GIGA offers ever greater operational reliability with the standby pump in the twin-head pump version.

Construction

High-efficiency in-line twin-head pump with EC motor and electronic power adjustment in glanded pump construction. Version as single-stage low-pressure centrifugal pump with flange connection and mechanical seal.

Application

The pumping of heating water (in accordance with VDI 2035), cold water and water-glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Equipment/function

Operating modes

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

- PID-Control

- Constant speed (n=constant)

- Green button and display

- Differential pressure setpoint setting

- Setting the speed (manual control mode)

- Setting the operating mode

- Setting the pump ON/OFF

- Configuration of all operating parameters

- Fault acknowledgement

- "Overriding Off" control input

- “External pump cycling” control input (only effective in twin-head pump operation)

- Analogue input 0 – 10 V, 0 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 2 – 10 V, 4 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 0 – 10 V for actual value signal from pressure sensor

- Analogue input 2 – 10 V, 0 – 20 mA, 4 – 20 mA for actual value signal from pressure sensor

- Collective fault signal SSM

- Collective run signal SBM

- Infrared interface for wireless data exchange with IR-Monitor/IR-Stick

- Plug-in position for Wilo IF-Modules (Modbus, BACnet, CAN, PLR, LON) for connection to building automation

- Full motor protection with integrated trip electronics

- Access disable

- Main/standby operation (automatic fault-actuated switchover)

- Pump cycling main/standby operation after 24 hours

- Parallel operation

- Parallel operation (efficiency-optimised peak-load activation and deactivation)

- Pump

- Installation and operating instructions

- Technical data

- Permitted temperature range of the fluid: -20 °C to +140 °C

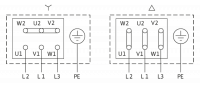

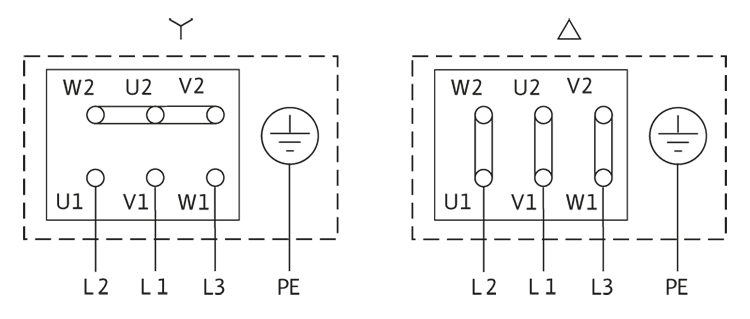

- Mains connection 3~480 V ±10 %, 50/60 Hz, 3~440 V ±10 %, 50/60 Hz, 3~400 V ±10 %, 50/60 Hz, 3~380 V -5 % +10 %, 50/60 Hz

- Protection class IP55

- Nominal diameter DN 40 to DN 100

- Max. operating pressure 16 bar

- Pump housing and lantern: EN-GJL-250

- Impeller: PPS-GF40 or EN-GJL-200 depending on the type

- Shaft: 1.4122

- Mechanical seal: AQEGG; other mechanical seals on request

Nomaiņas sūknis - Parastais Apmaiņats komplekts

Komentāri

Produkta informācija

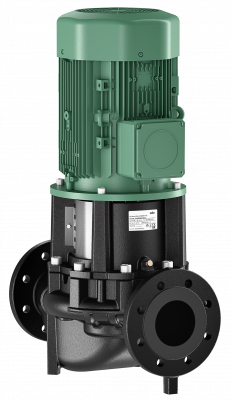

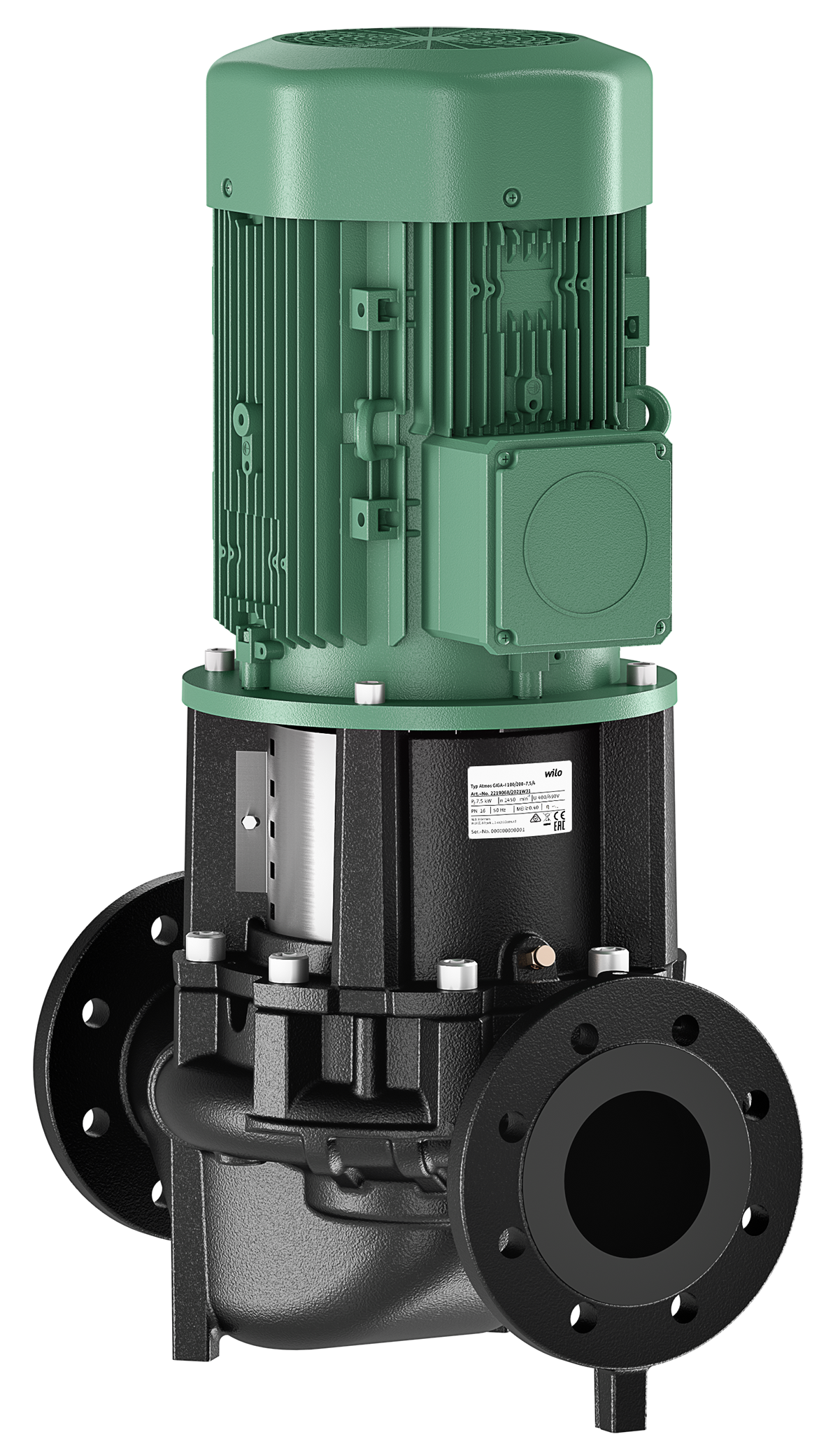

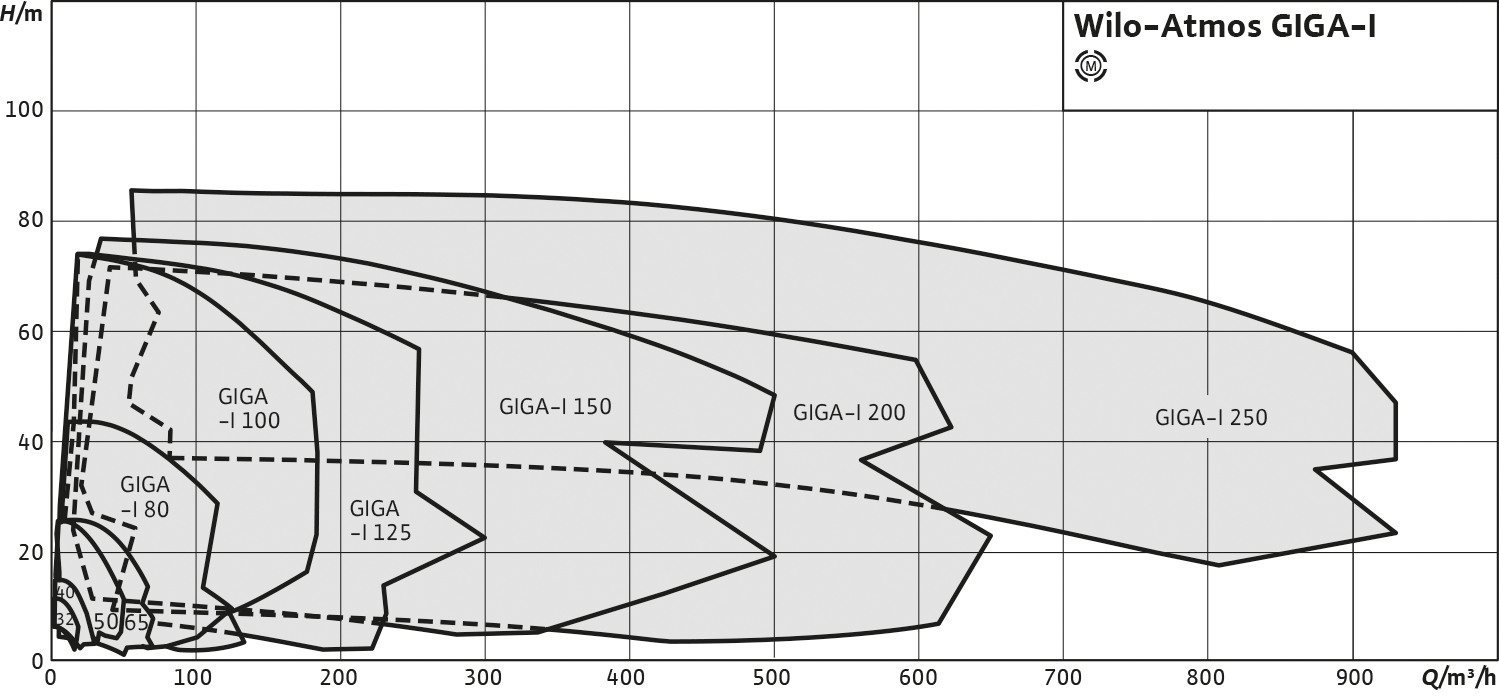

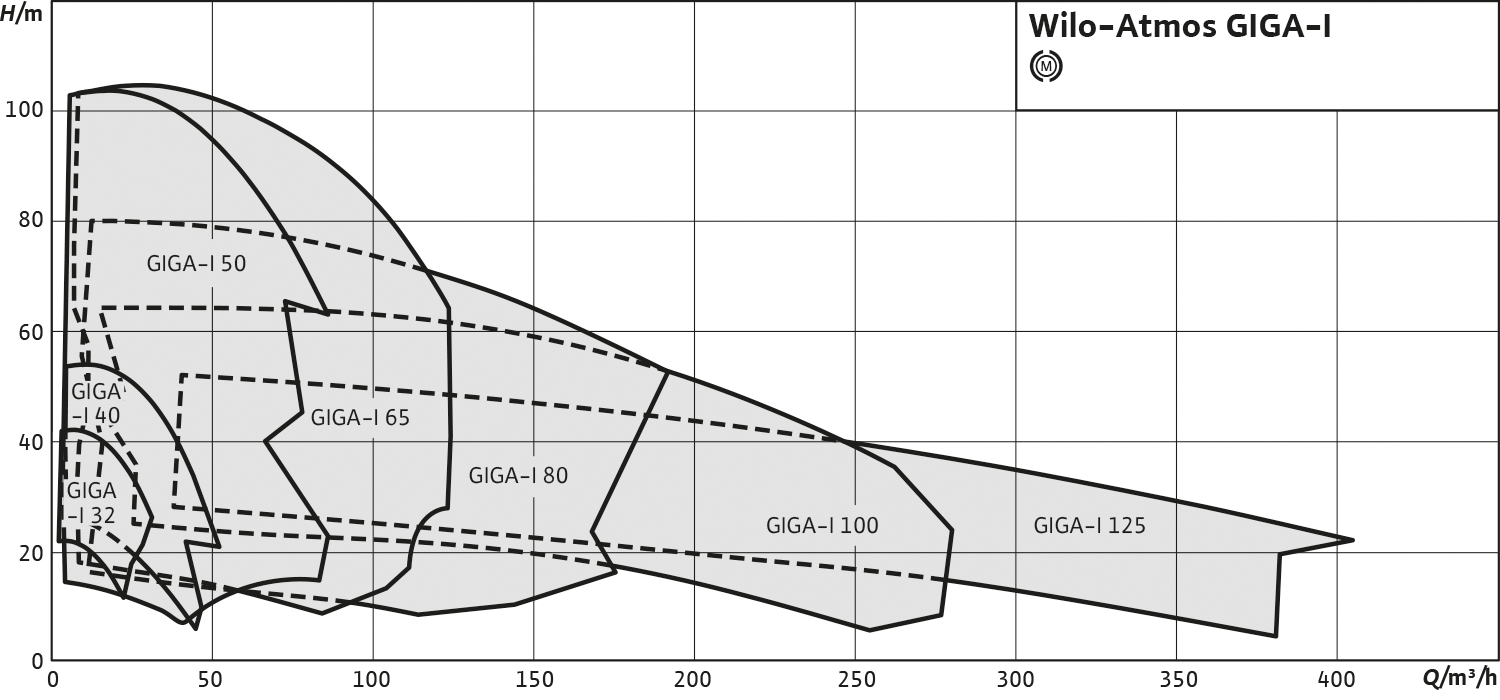

Atmos GIGA-I 100/130-15/2

Inline konstrukcijas sausā rotora sūknis ar atloka savienojumu.

Pielietojums

Apkures ūdens (saskaņā ar VDI 2035), aukstā ūdens un ūdens glikola maisījumu bez abrazīvām sastāvdaļām sūknēšanai apkures, aukstā ūdens un dzesēšanas sistēmās.

Tehniskie parametri

- Pieļaujamais šķidruma temperatūras diapazons -20 °C līdz +140 °C

- Maks. apkārtējā gaisa temperatūra: 40 °C

- Elektrotīkla pieslēgums 3~400 V, 50 Hz (citi pieejami pēc pieprasījuma)

- Aizsardzības pakāpe IP55

- Nominālais diametrs DN 32 līdz DN 250

- Standarta modelis, paredzēts darba spiedienam: 13 bar (līdz +140 °C) / 16 bar (līdz +120 °C)

- Sūkņa korpuss un kupols: Standarts: EN-GJL-250;

- Darba rats: Standarts: EN-GJL-200; speciālais modelis: Bronza CuSn 10, nerūsējošais tērauds 1.4408

- Vārpsta: 1.4122

- Gala blīvējums: AQEGG; citi gala blīvējumi pēc pieprasījuma

Vienrindas vienpakāpes zemspiediena centrbēdzes sūknis ar:

- Gala blīvējums

- Atloka pieslēgumu un spiediena mērīšanas pieslēgumu R 1/8

- Starpkorpuss

- Savienojuma elements

- IEC standarta motors

- Sūknis

- Uzstādīšanas un ekspluatācijas instrukcija

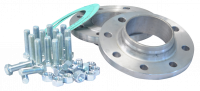

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 115 mm.

- Outer diameter: 152 mm.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.