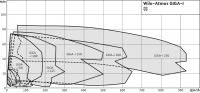

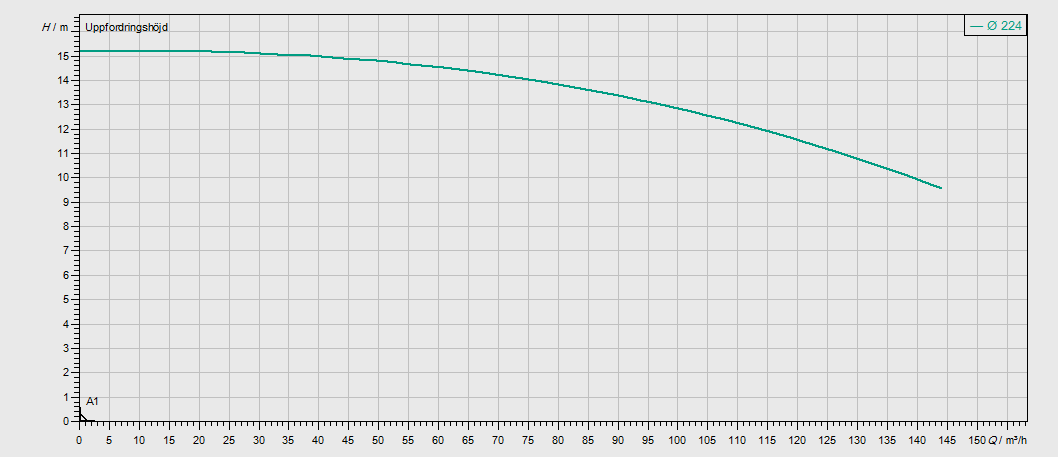

Esošais Sūknis - Cirkulācija Sūkņa līkne

Nomaiņas sūknis - High Efficiency Standarta Apmaiņats komplekts

Komentāri

Produkta informācija

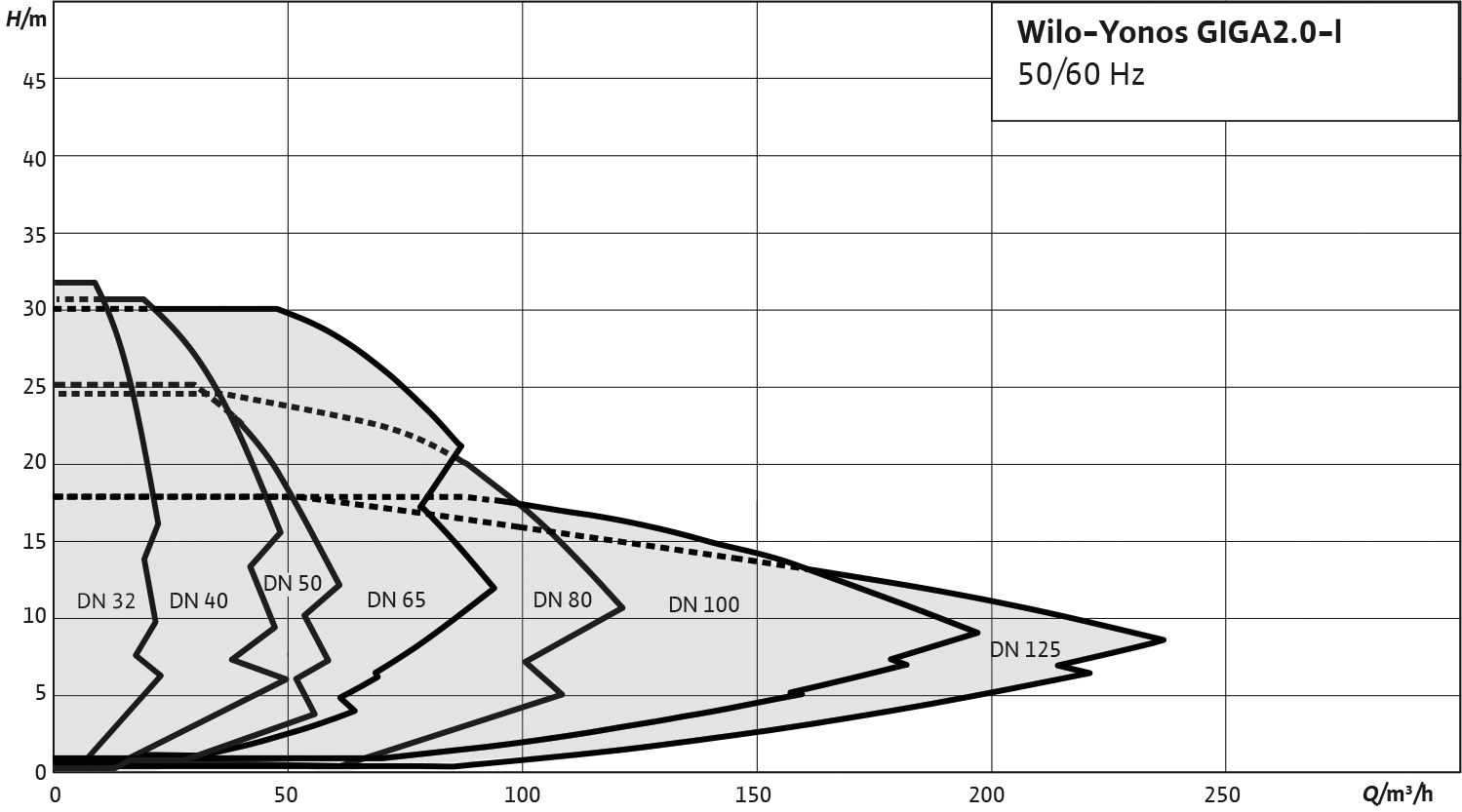

Yonos GIGA2.0-I 125/1-17/7,5

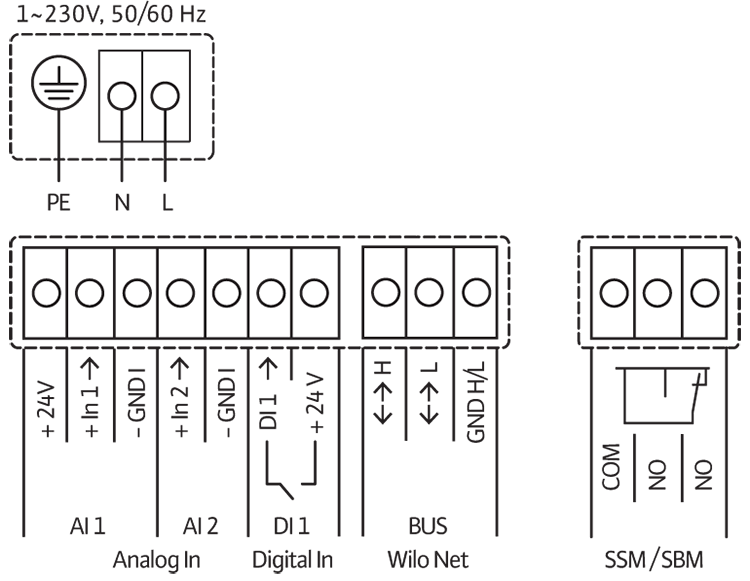

Wilo-Yonos GIGA2.0-I ir elektroniski regulējams Inline sausā rotora sūknis, kas piemērots liela ūdens daudzuma sūknēšanai lielā sūknēšanas augstumā. Pateicoties IE5 EC motora tehnoloģijai un pārbaudītajai sūkņa hidraulikai (MEI ≥0,4), tas nodrošina vienlīdz augstu enerģijas efektivitāti un uzticamību. Jau pazīstamā zaļās pogas tehnoloģija, skaidri pārskatāmās izvēlnes un krāsu displejs nodrošina ļoti vienkāršu vadību. Analogās un digitālās saskarnes piedāvā integrācijas iespēju ēkas automatizācijā.

Nomaiņas sūknis - Parastais Apmaiņats komplekts

Komentāri

Produkta informācija

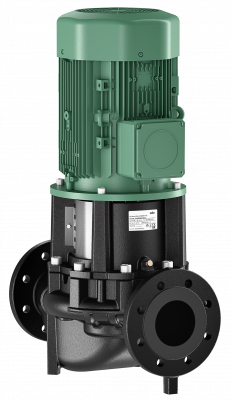

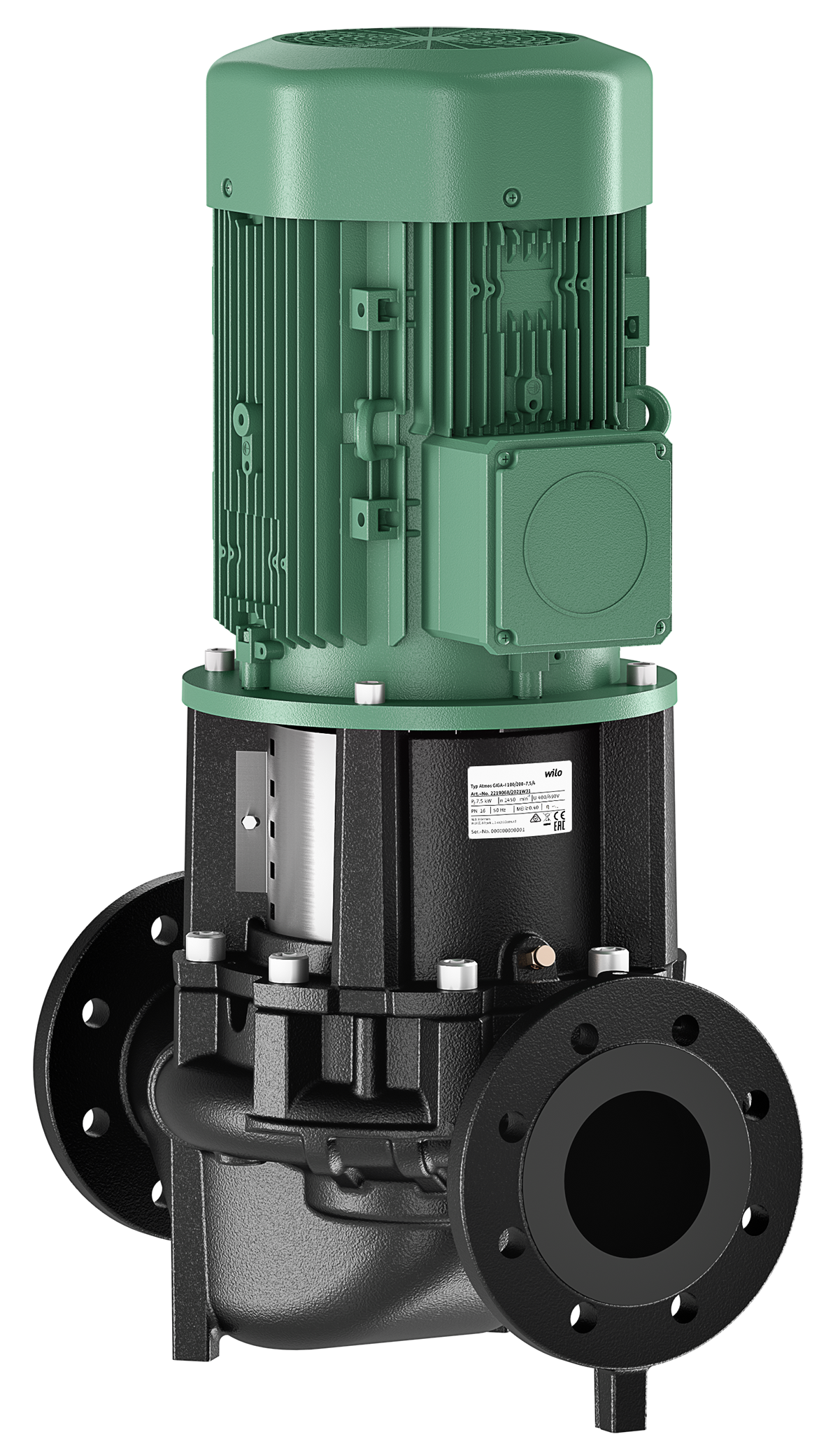

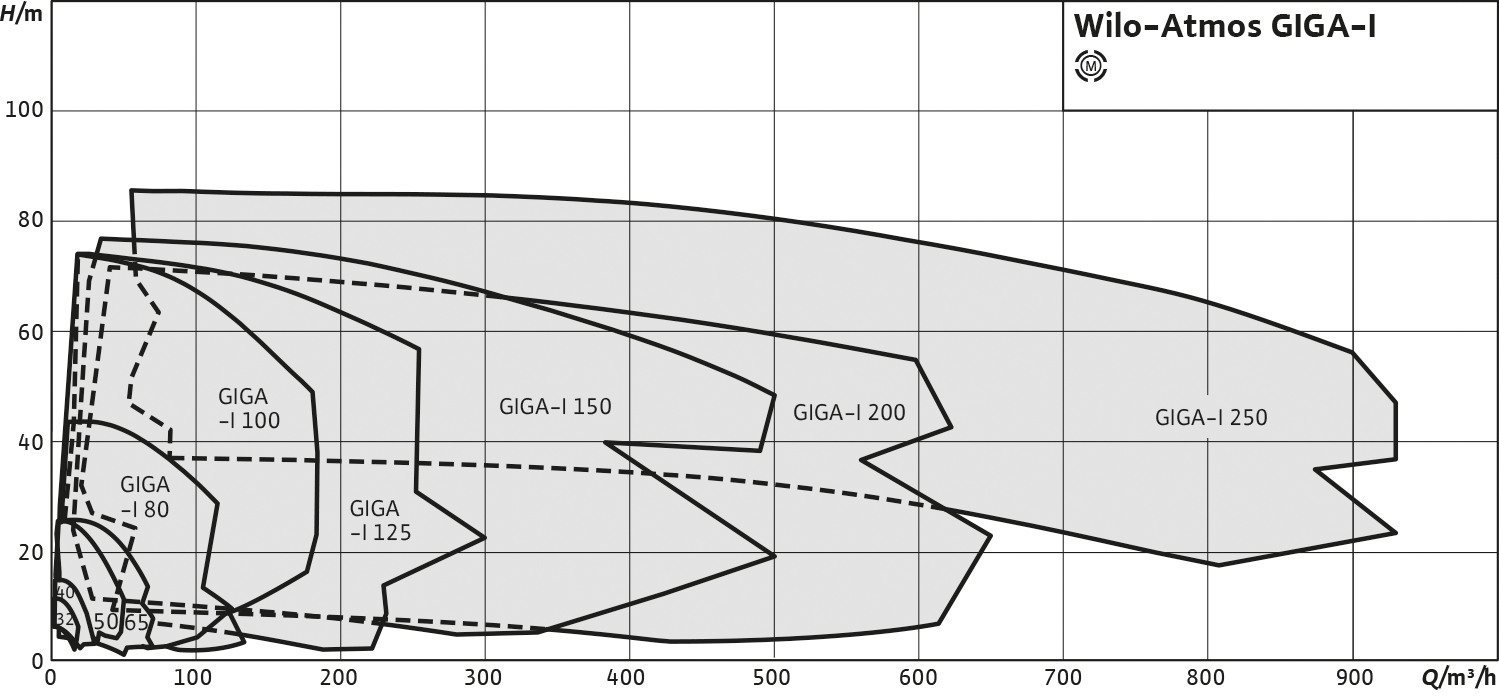

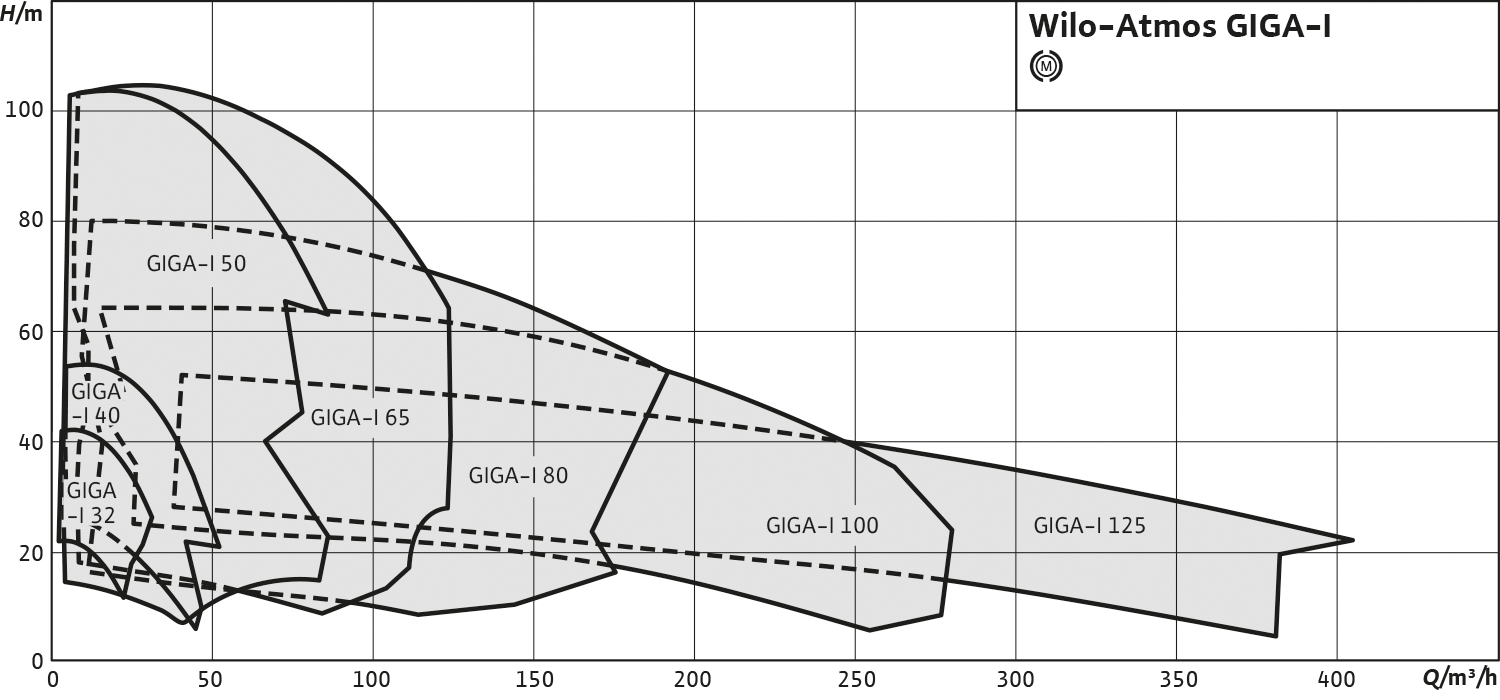

Atmos GIGA-I 125/220-5,5/4

Inline konstrukcijas sausā rotora sūknis ar atloka savienojumu.

Pielietojums

Apkures ūdens (saskaņā ar VDI 2035), aukstā ūdens un ūdens glikola maisījumu bez abrazīvām sastāvdaļām sūknēšanai apkures, aukstā ūdens un dzesēšanas sistēmās.

Tehniskie parametri

- Pieļaujamais šķidruma temperatūras diapazons -20 °C līdz +140 °C

- Maks. apkārtējā gaisa temperatūra: 40 °C

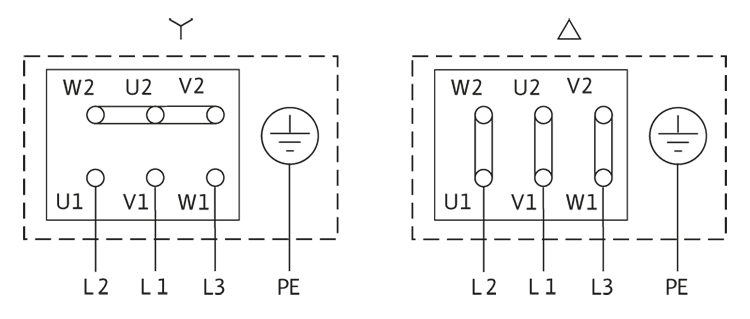

- Elektrotīkla pieslēgums 3~400 V, 50 Hz (citi pieejami pēc pieprasījuma)

- Aizsardzības pakāpe IP55

- Nominālais diametrs DN 32 līdz DN 250

- Standarta modelis, paredzēts darba spiedienam: 13 bar (līdz +140 °C) / 16 bar (līdz +120 °C)

- Sūkņa korpuss un kupols: Standarts: EN-GJL-250;

- Darba rats: Standarts: EN-GJL-200; speciālais modelis: Bronza CuSn 10, nerūsējošais tērauds 1.4408

- Vārpsta: 1.4122

- Gala blīvējums: AQEGG; citi gala blīvējumi pēc pieprasījuma

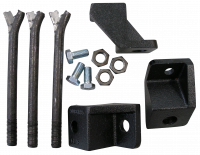

Vienrindas vienpakāpes zemspiediena centrbēdzes sūknis ar:

- Gala blīvējums

- Atloka pieslēgumu un spiediena mērīšanas pieslēgumu R 1/8

- Starpkorpuss

- Savienojuma elements

- IEC standarta motors

- Sūknis

- Uzstādīšanas un ekspluatācijas instrukcija

- Complete kit.

- For mounting on foundations.

- Comes in a bag.

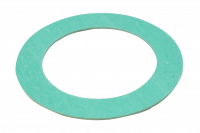

- Thickness: 2 mm.

- Inner diameter: 142 mm.

- Outer diameter: 195 mm.

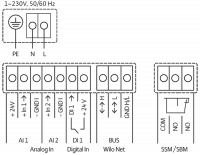

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.