Esošais Sūknis - Cirkulācija

Nomaiņas sūknis - Parastais Apmaiņats komplekts

Komentāri

Produkta informācija

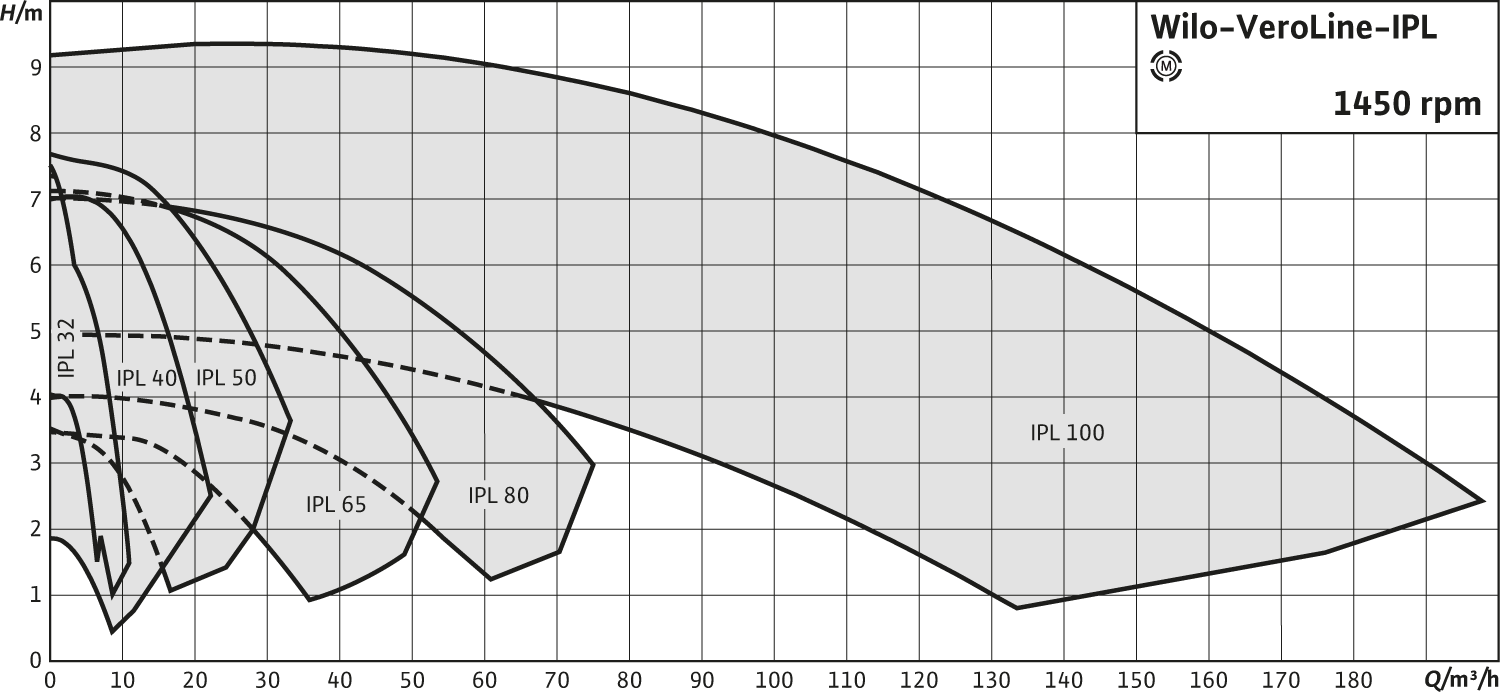

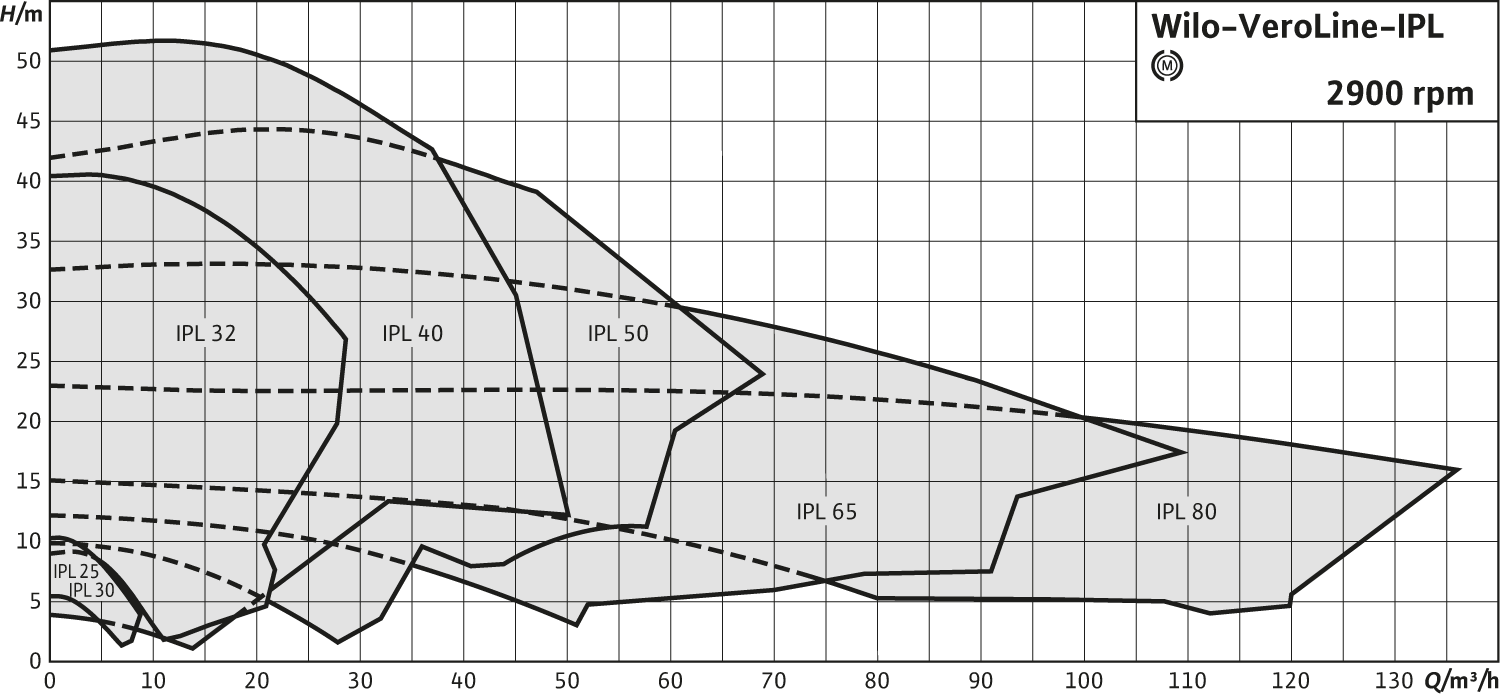

IPL 65/110-0,25/4

Your advantages

- High standard of corrosion protection thanks to cataphoretic coating

- Standard condensate drainage holes in the motor housings and lanterns

- Series design: motor with one-piece shaft

- Version N: Standard motor V1 with stainless steel plug shaft

- Bidirectional, force-flushed mechanical seal

Glanded pump in in-line design with screwed connection or flange connection.

Application

Pumping of heating water (acc. to VDI 2035), cold water and water/glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Scope of delivery

- Pump

- Installation and operating instructions

- Permissible temperature range -20 °C to +120 °C

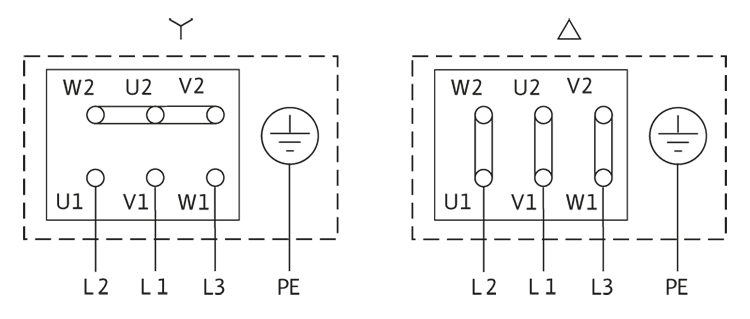

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP 55

- Nominal diameter Rp 1 to DN 100

- Max. operating pressure 10 bar (special version: 16 bar)

- Pump housing and lantern: EN-GJL-250

- Impeller: PPO fibreglass-reinforced EN-GJL-200 (depending on pump type)

- Shaft: 1.4021

- Mechanical seal: AQEGG; other mechanical seals on request

Single-stage, low-pressure centrifugal pump in in-line design with:

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Motor with one-piece shaft

- Made of steel.

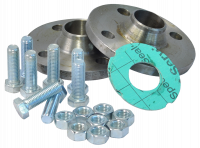

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 77 mm.

- Outer diameter: 115 mm.

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Terminals for external, potential-free activation/deactivation

- Connection terminal strip

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Fault signal light

- Terminals for external, potential-free activation/deactivation

- Potential-free contacts for external run signal (SBM) and fault signal (SSM)

- Connection terminal strip

- Switchgear SK 622N

- 4 threaded cable connections M20

- Installation and operating instructions