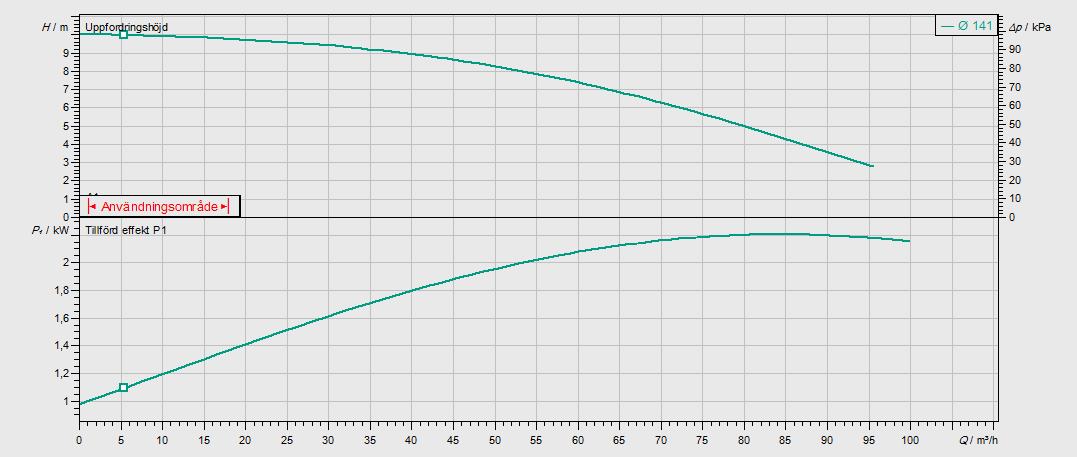

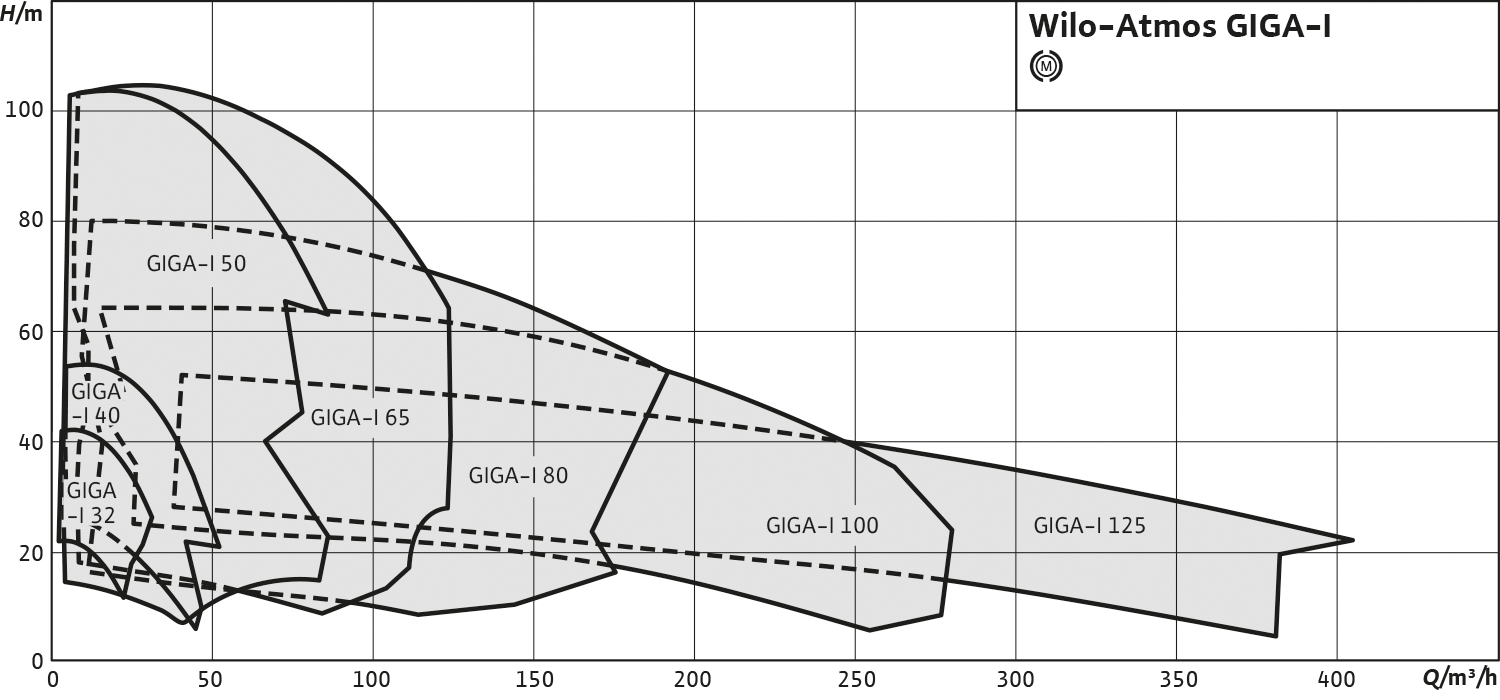

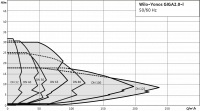

Esošais Sūknis - Cirkulācija Sūkņa līkne

Nomaiņas sūknis - High Efficiency Standarta Apmaiņats komplekts

Komentāri

Produkta informācija

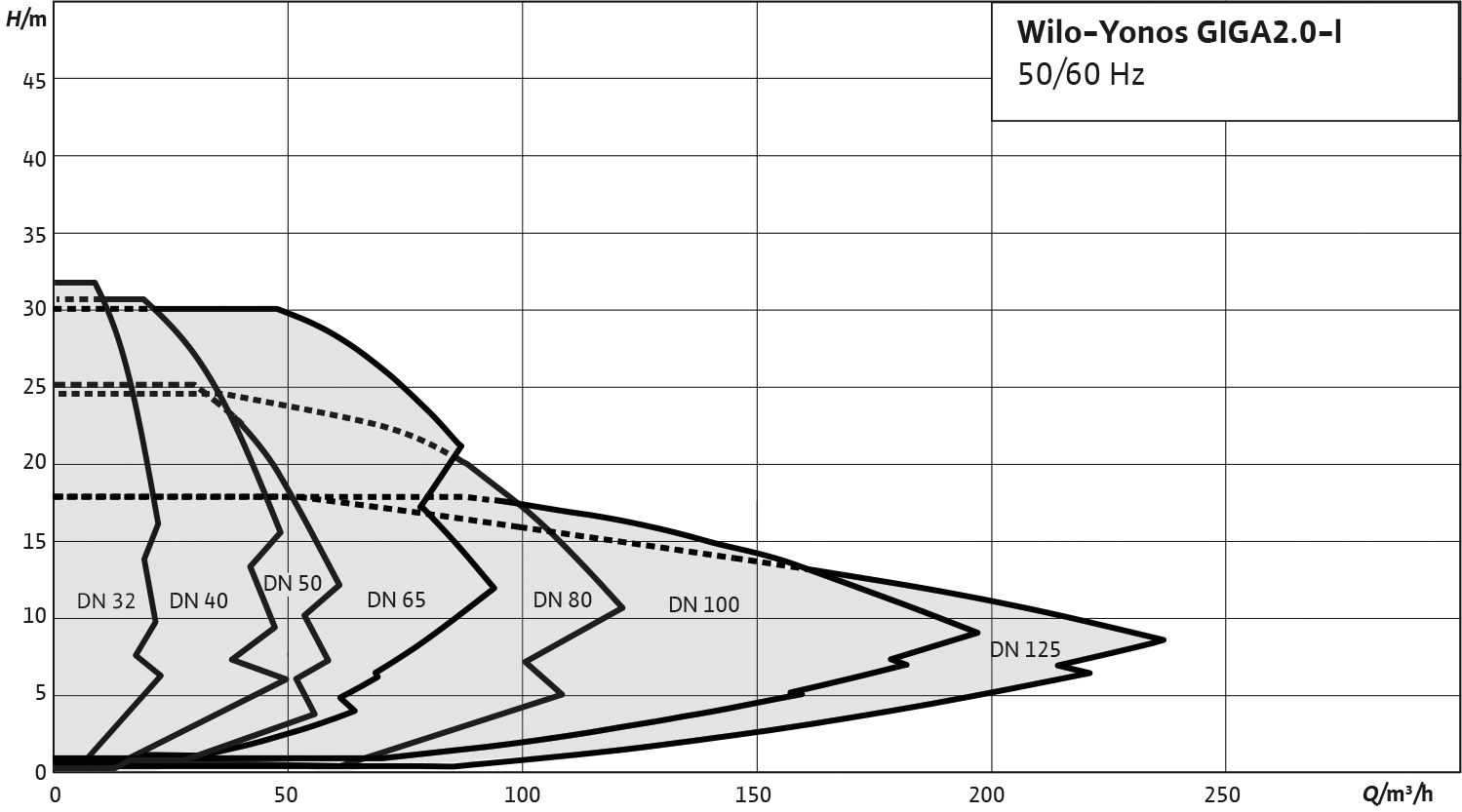

Yonos GIGA2.0-I 80/1-12/3,0

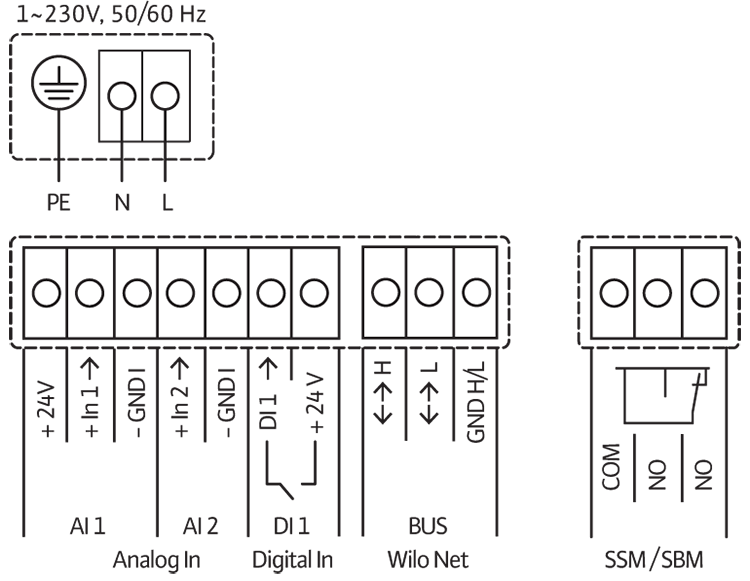

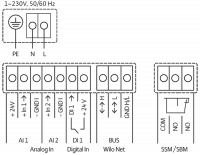

Wilo-Yonos GIGA2.0-I ir elektroniski regulējams Inline sausā rotora sūknis, kas piemērots liela ūdens daudzuma sūknēšanai lielā sūknēšanas augstumā. Pateicoties IE5 EC motora tehnoloģijai un pārbaudītajai sūkņa hidraulikai (MEI ≥0,4), tas nodrošina vienlīdz augstu enerģijas efektivitāti un uzticamību. Jau pazīstamā zaļās pogas tehnoloģija, skaidri pārskatāmās izvēlnes un krāsu displejs nodrošina ļoti vienkāršu vadību. Analogās un digitālās saskarnes piedāvā integrācijas iespēju ēkas automatizācijā.

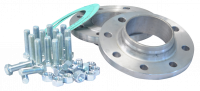

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

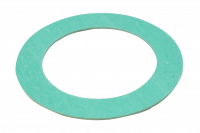

- Thickness: 2 mm.

- Inner diameter: 90 mm.

- Outer diameter: 132 mm.

The IR-Stick in combination with the supplied Wilo software (CD-ROM), makes it possible to read out and save data records for pumps as well as send previously defined pump settings.

- IR carrier frequency: 33 kHz / 455 kHz

- Software upgrade: via USB

- Inaccessibly installed pumps

- Quick configuration of pumps

- Extensive operating information

- Detailed fault diagnosis

- Statistical functions

- Special settings/control modes for special requirements

- Protection against unauthorised access

- Archiving of pump data sets

For all pumps and standard motors for measuring the direction of rotation, rotating field frequency and current operating status.

Direction of rotation checking device also for all conventional pumps with alternating or three-phase motor.

Industrial standard due to its sturdy and robust plastic casing, graphical display with scratch-resistant monitor screen.

One-button manual operation level for the Wilo high-efficiency and energy-saving pumps, additional 4 buttons for:

- IR-Monitor on/off

- Lighting on/off

- Information/help

- Electrical and hydraulic actual values

- Power supply and duty point of the pump

- Statistical values

- Service information

- Device settings.

- Self-test pump

- Self-test IR-Monitor

- Battery status check.

Nomaiņas sūknis - Parastais Apmaiņats komplekts

Komentāri

Produkta informācija

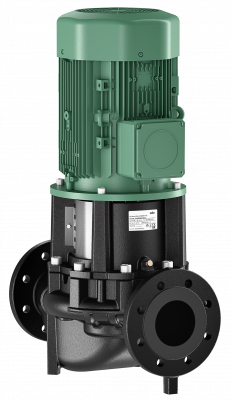

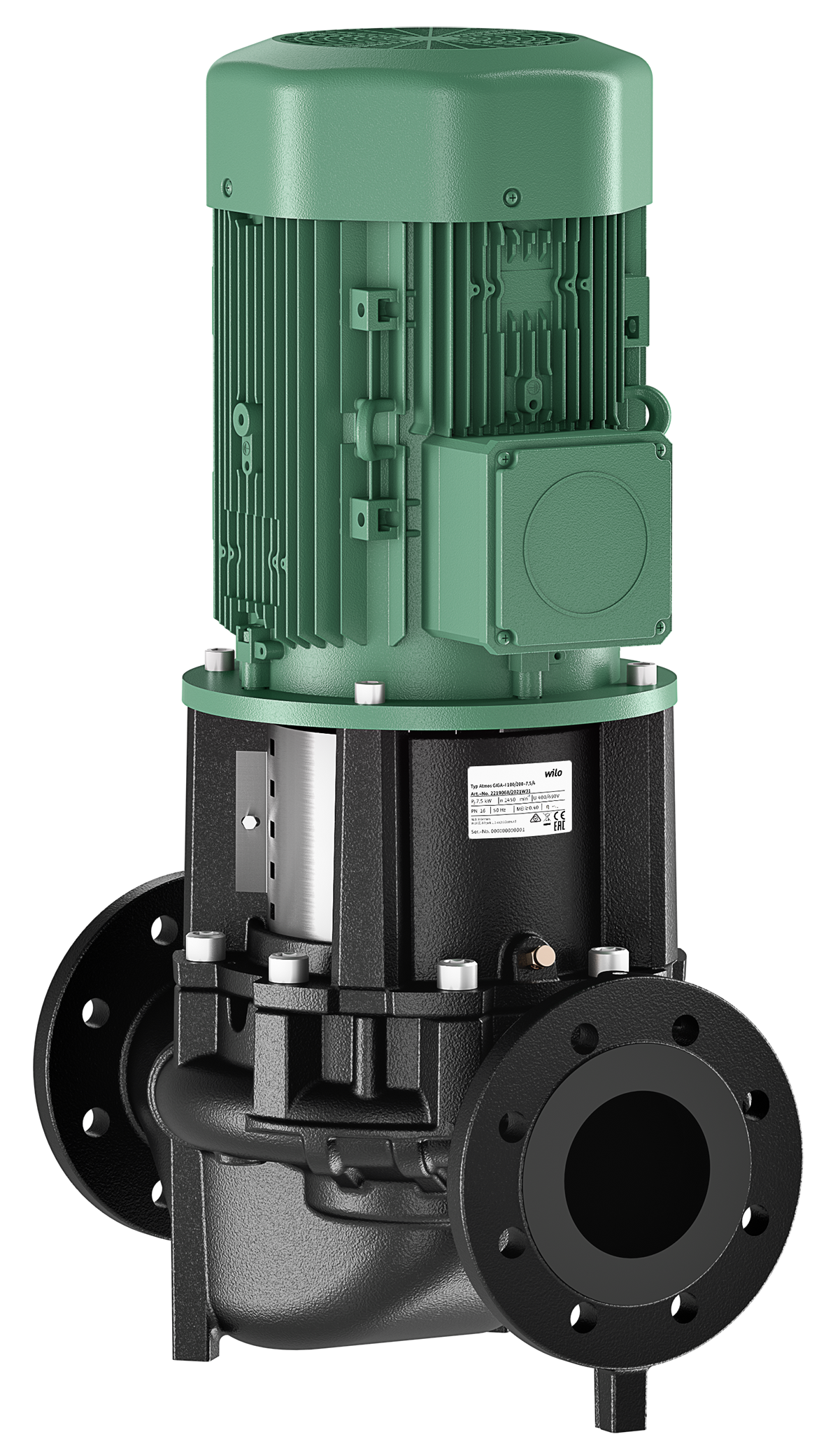

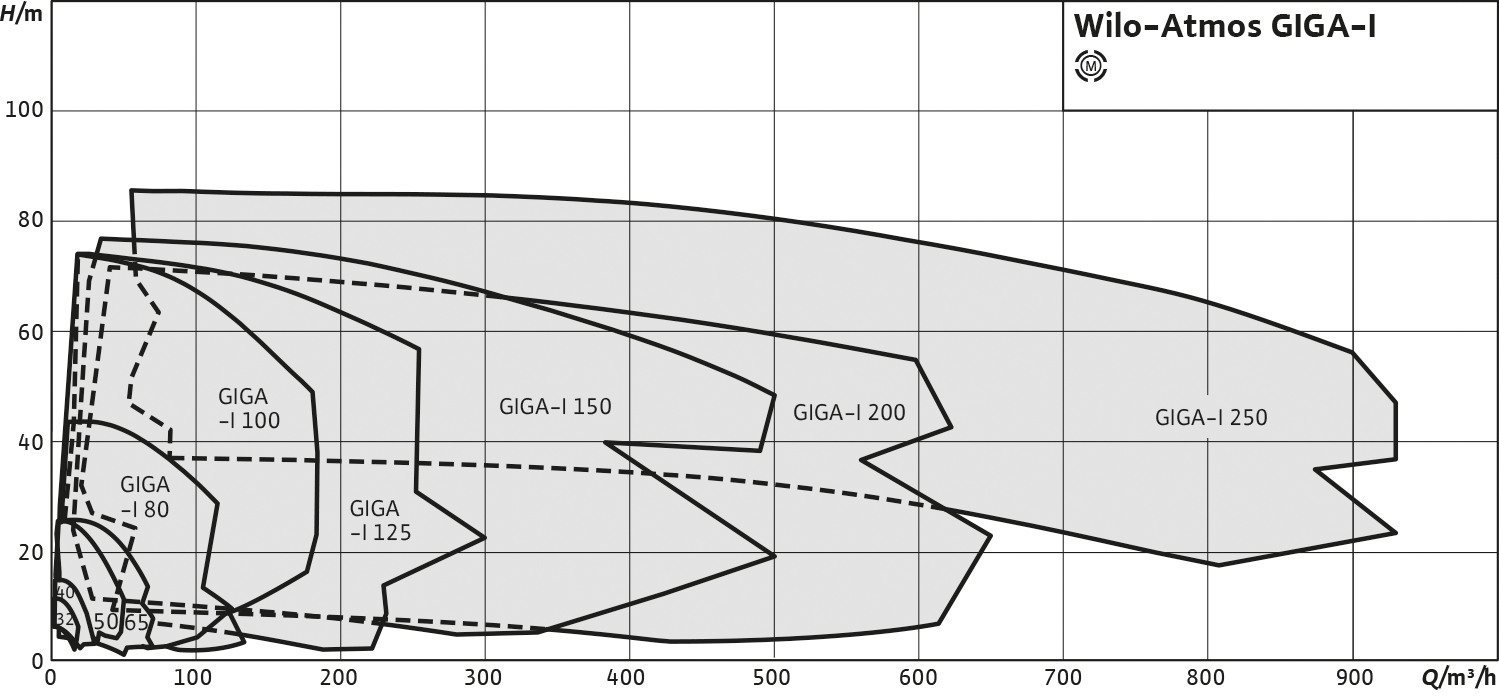

Atmos GIGA-I 80/160-2,2/4

Inline konstrukcijas sausā rotora sūknis ar atloka savienojumu.

Pielietojums

Apkures ūdens (saskaņā ar VDI 2035), aukstā ūdens un ūdens glikola maisījumu bez abrazīvām sastāvdaļām sūknēšanai apkures, aukstā ūdens un dzesēšanas sistēmās.

Tehniskie parametri

- Pieļaujamais šķidruma temperatūras diapazons -20 °C līdz +140 °C

- Maks. apkārtējā gaisa temperatūra: 40 °C

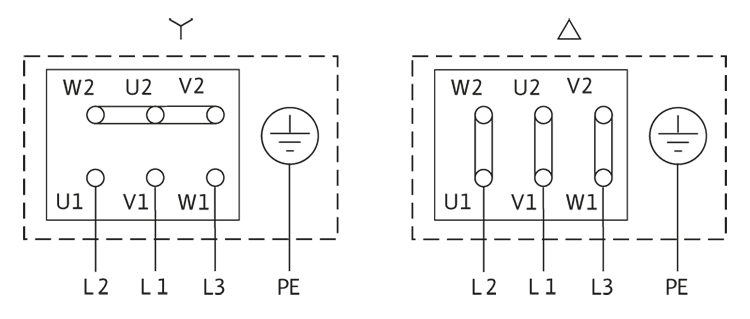

- Elektrotīkla pieslēgums 3~400 V, 50 Hz (citi pieejami pēc pieprasījuma)

- Aizsardzības pakāpe IP55

- Nominālais diametrs DN 32 līdz DN 250

- Standarta modelis, paredzēts darba spiedienam: 13 bar (līdz +140 °C) / 16 bar (līdz +120 °C)

- Sūkņa korpuss un kupols: Standarts: EN-GJL-250;

- Darba rats: Standarts: EN-GJL-200; speciālais modelis: Bronza CuSn 10, nerūsējošais tērauds 1.4408

- Vārpsta: 1.4122

- Gala blīvējums: AQEGG; citi gala blīvējumi pēc pieprasījuma

Vienrindas vienpakāpes zemspiediena centrbēdzes sūknis ar:

- Gala blīvējums

- Atloka pieslēgumu un spiediena mērīšanas pieslēgumu R 1/8

- Starpkorpuss

- Savienojuma elements

- IEC standarta motors

- Sūknis

- Uzstādīšanas un ekspluatācijas instrukcija

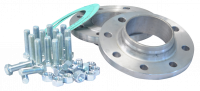

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

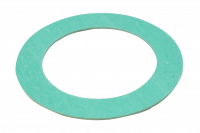

- Thickness: 2 mm.

- Inner diameter: 90 mm.

- Outer diameter: 132 mm.

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Terminals for external, potential-free activation/deactivation

- Connection terminal strip

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Fault signal light

- Terminals for external, potential-free activation/deactivation

- Potential-free contacts for external run signal (SBM) and fault signal (SSM)

- Connection terminal strip

- Switchgear SK 622N

- 4 threaded cable connections M20

- Installation and operating instructions

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.