Esošais Sūknis - Cirkulācija

Nomaiņas sūknis - High Efficiency Standarta Apmaiņats komplekts

Komentāri

Produkta informācija

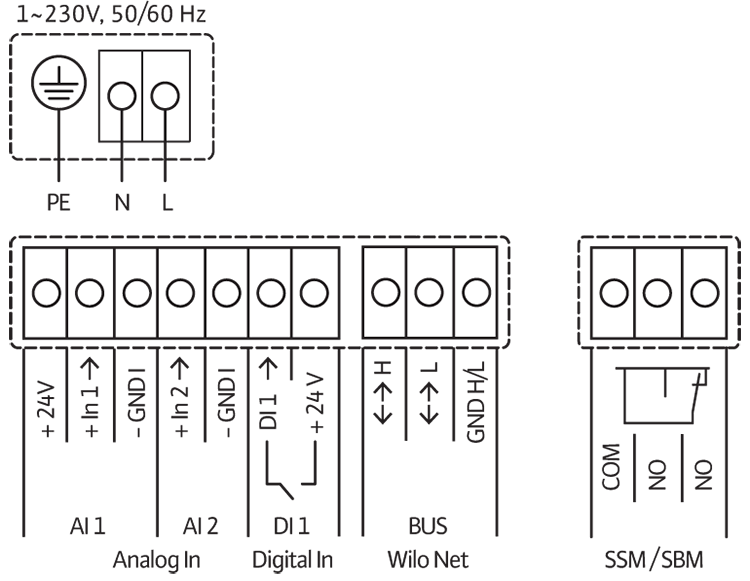

Yonos GIGA2.0-I 40/1-10/0,75

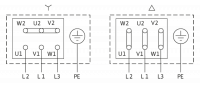

Wilo-Yonos GIGA2.0-I ir elektroniski regulējams Inline sausā rotora sūknis, kas piemērots liela ūdens daudzuma sūknēšanai lielā sūknēšanas augstumā. Pateicoties IE5 EC motora tehnoloģijai un pārbaudītajai sūkņa hidraulikai (MEI ≥0,4), tas nodrošina vienlīdz augstu enerģijas efektivitāti un uzticamību. Jau pazīstamā zaļās pogas tehnoloģija, skaidri pārskatāmās izvēlnes un krāsu displejs nodrošina ļoti vienkāršu vadību. Analogās un digitālās saskarnes piedāvā integrācijas iespēju ēkas automatizācijā.

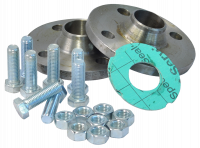

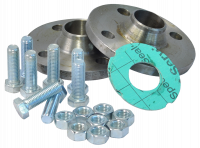

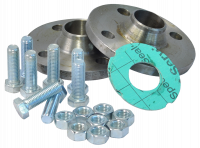

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

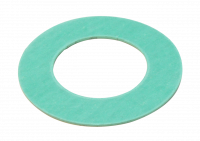

- Thickness: 2 mm.

- Inner diameter: 49 mm.

- Outer diameter: 85 mm.

The IR-Stick in combination with the supplied Wilo software (CD-ROM), makes it possible to read out and save data records for pumps as well as send previously defined pump settings.

- IR carrier frequency: 33 kHz / 455 kHz

- Software upgrade: via USB

- Inaccessibly installed pumps

- Quick configuration of pumps

- Extensive operating information

- Detailed fault diagnosis

- Statistical functions

- Special settings/control modes for special requirements

- Protection against unauthorised access

- Archiving of pump data sets

For all pumps and standard motors for measuring the direction of rotation, rotating field frequency and current operating status.

Direction of rotation checking device also for all conventional pumps with alternating or three-phase motor.

Industrial standard due to its sturdy and robust plastic casing, graphical display with scratch-resistant monitor screen.

One-button manual operation level for the Wilo high-efficiency and energy-saving pumps, additional 4 buttons for:

- IR-Monitor on/off

- Lighting on/off

- Information/help

- Electrical and hydraulic actual values

- Power supply and duty point of the pump

- Statistical values

- Service information

- Device settings.

- Self-test pump

- Self-test IR-Monitor

- Battery status check.

Nomaiņas sūknis - High Efficiency Standarta Apmaiņats komplekts

Komentāri

Produkta informācija

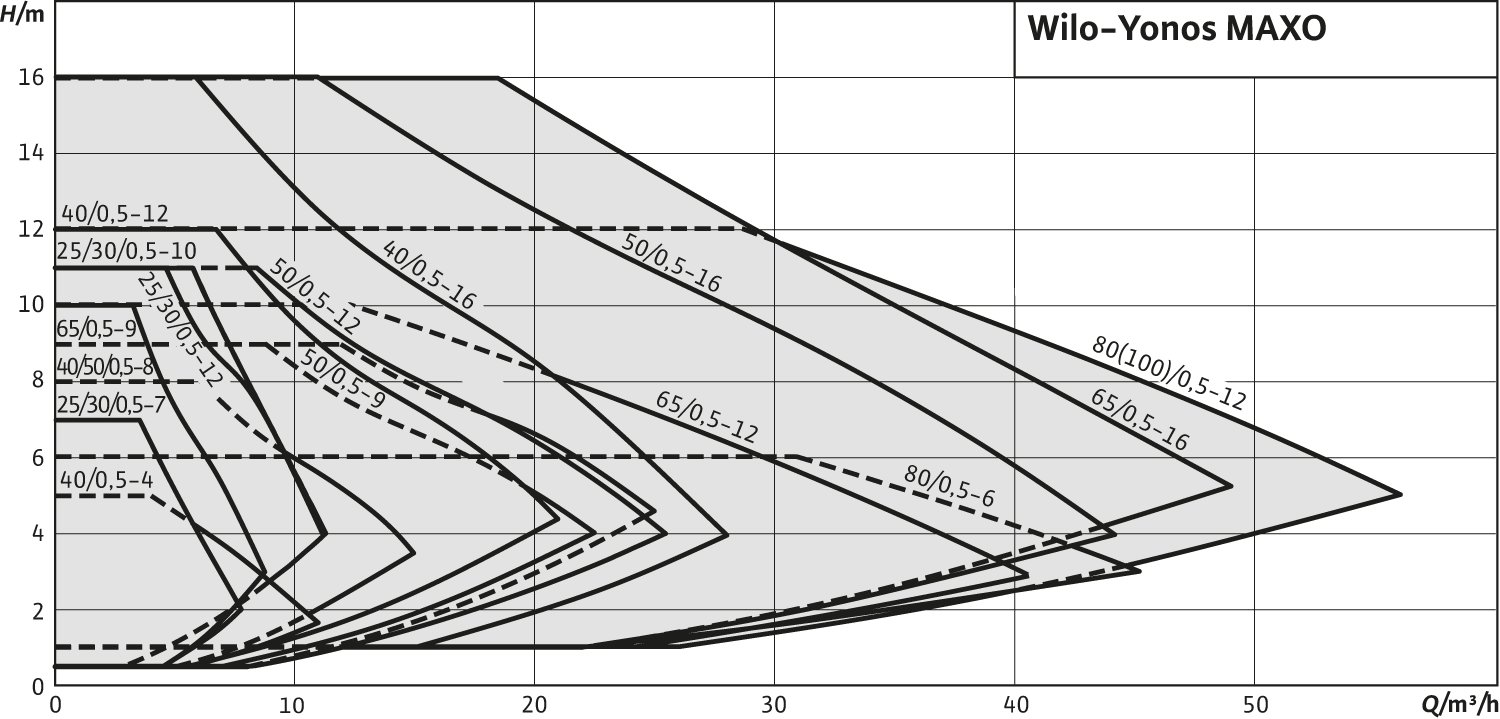

Yonos MAXO 40/0,5-16

Specifika/produkta priekšrocības

- Gaismas diodes rādījums sniedz pilnīgu pārskatāmību par nepieciešamo sūknēšanas augstumu, ātruma pakāpi vai iespējamām kļūdām

- Vienkārša iestatīšana ar trīs ātruma pakāpēm, nomainot neregulējamu standarta sūkni

- Vienkāršots pieslēgums elektrotīklam ar Wilo spraudni

- Iekārtas pieejamības nodrošinājums, izmantojot bojājumu signālu

- Kompakta konstrukcija un pārbaudīta vienkārša apkalpošana

Slapjā rotora cirkulācijas sūknis ar skrūvsavienojuma vai atloka pieslēgumu, EC motors ar automātisku jaudas pielāgošanu

Ieliktnis

Visu veidu karstā ūdens apkures sistēmas, kondicionēšanas iekārtas, slēgti dzesēšanas loki, rūpnieciskās cirkulācijas iekārtas.

Aprīkojums/darbība

Ekspluatācijas veidi

- Δp-c konstantai spiedienu starpībai

- Δp-v mainīgai spiedienu starpībai

- n = konstants (3 apgriezienu skaita pakāpes)

- Ekspluatācijas veida iestatīšana

- Sūkņa jaudas (sūknēšanas augstuma) iestatīšana

- Apgriezienu skaita pakāpju iestatīšana

- Jaudas bezpakāpju pielāgošana atkarībā no ekspluatācijas veida

- Atbloķēšanas funkcija

- Softstart

- Integrēta pilna motora aizsardzība

- Bojājuma signāls (bezpotenciāla atvērējs)

- Bojājuma signāllampiņa

- Gaismas diožu segmentu rādījums sūkņa datu un traucējuma koda indikācijai

- Iestatītā apgriezienu skaita rādījums (C1, C2 vai C3)

- Atslēgas vieta pie sūkņa korpusa (sūkņiem ar cauruļu skrūvsavienojumiem)

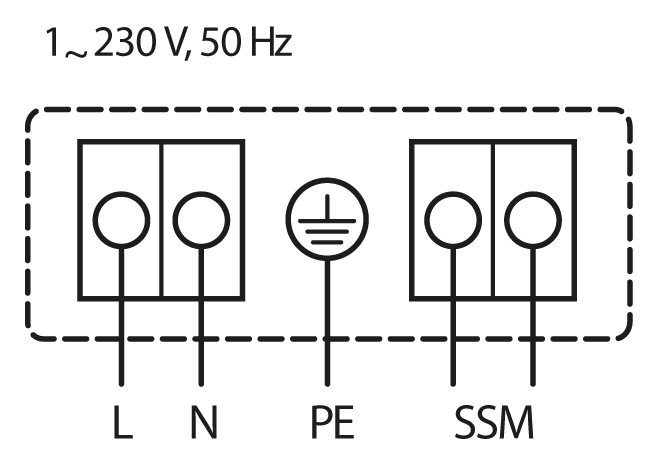

- Ātrais elektropieslēgums ar Wilo spraudni Paredzēts tīkla un SM kabeļa pieslēgumam, ar iebūvēto stiepes atslodzi

- Atloka sūkņiem: atloka modeļi

- Standarta modelis sūkņiem DN 40 līdz DN 65: kombinētais atloks PN 6/10 (atloks PN 16 atbilstoši EN 1092-2) pretatlokiem PN 6 un PN 16

- Standarta modelis sūkņiem DN 80 / DN 100: Atloks PN 6 (konstruēts PN 16, atbilstoši EN 1092-2) pretatlokam PN 6

- Sūknis

- Iekļ. blīvējumi vītnes pieslēgumam

- Iekļ. paplāksnes atloka skrūvēm (pieslēguma nominālajam diametram DN 40 - DN 65)

- Iekļ. uzstādīšanas un ekspluatācijas instrukcija

- Pieļaujamais temperatūras diapazons no -20°C līdz +110°C

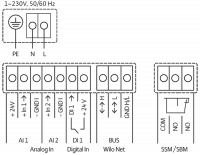

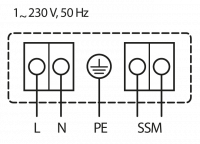

- Elektrotīkla pieslēgums 1~230 V, 50/60 Hz

- Aizsardzības pakāpe IPX4D

- Atloka pieslēgums DN 32 līdz DN 80

- Maks. darba spiediens standarta modelim: 6/10 bar vai 6 bar (speciālajam modelim: 10 bar)

- Sūkņa korpuss: pelēkais ķets ar KTL pārklājumu

- Vārpsta: nerūsējošs tērauds

- Gultņi: ogleklis, ar metālu impregnēts

- Rotors: plastmasa

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thermal insulation of pump housing in heating applications.

- Reduces heat loss by up to 85%.

- Energy saving, reduces operating costs.

- Protects the pump from external damage.

- 100% recyclable.

- Thickness: 2 mm.

- Inner diameter: 49 mm.

- Outer diameter: 85 mm.

The Wilo-Connect module Yonos MAXO is installed on the electronic module of the pump at the position of the Wilo plug.

Utilisation of the Wilo-Connect moduleYonos MAXO dispenses with external contactors and other switchgears as well as the associated installation workload. The load of customer-side switchgears (relays) due to high starting currents is reduced to a minimum by the Connect module Yonos MAXO.

Equipment/function

- Run signal display

- SSM collective fault signal as potential-free NC contact

- SBM collective run signal as potential-free NO contact

- Overriding Off control input (External Off)

- Integrated dual pump management with the functions:

- Main/standby operation with runtime-dependent (24 h) switchover from main to standby pump

- Fault-sensitive switchover to operational standby pump

Nomaiņas sūknis - Parastais Apmaiņats komplekts

Komentāri

Produkta informācija

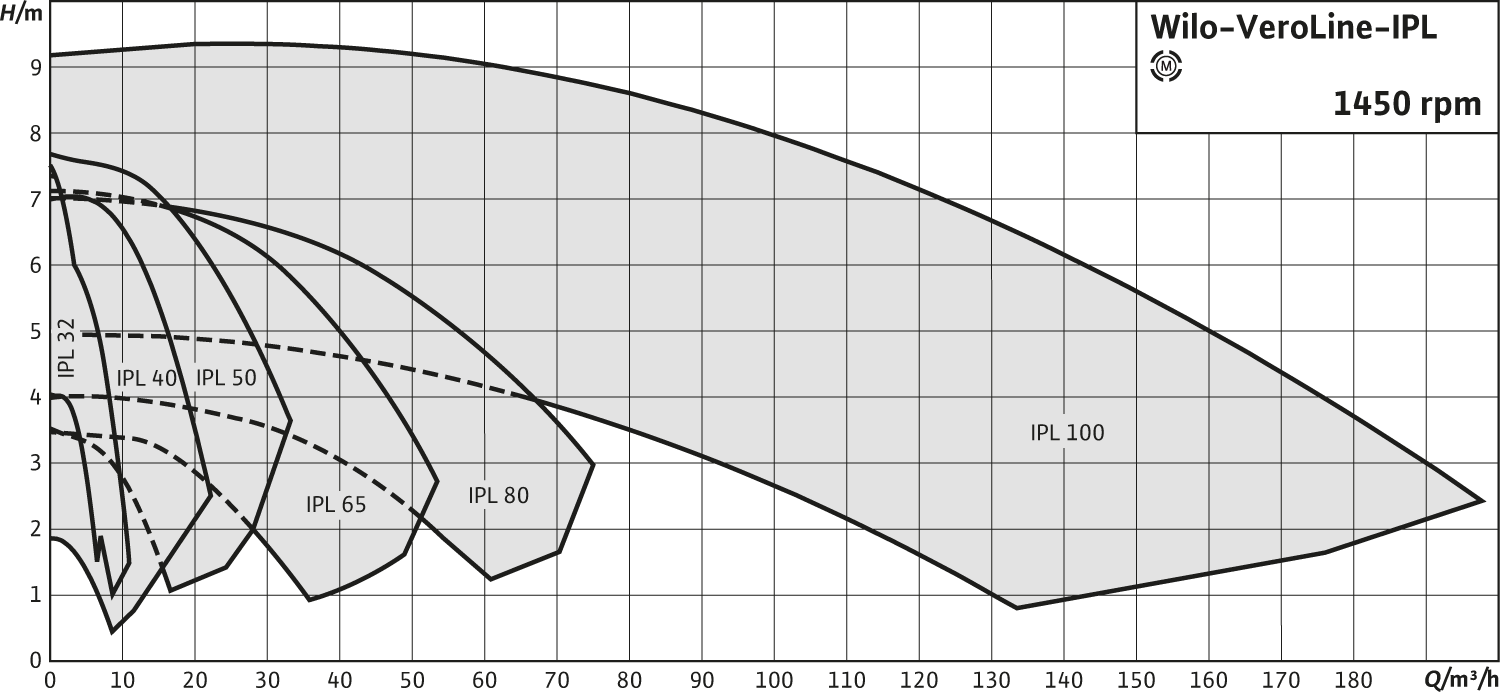

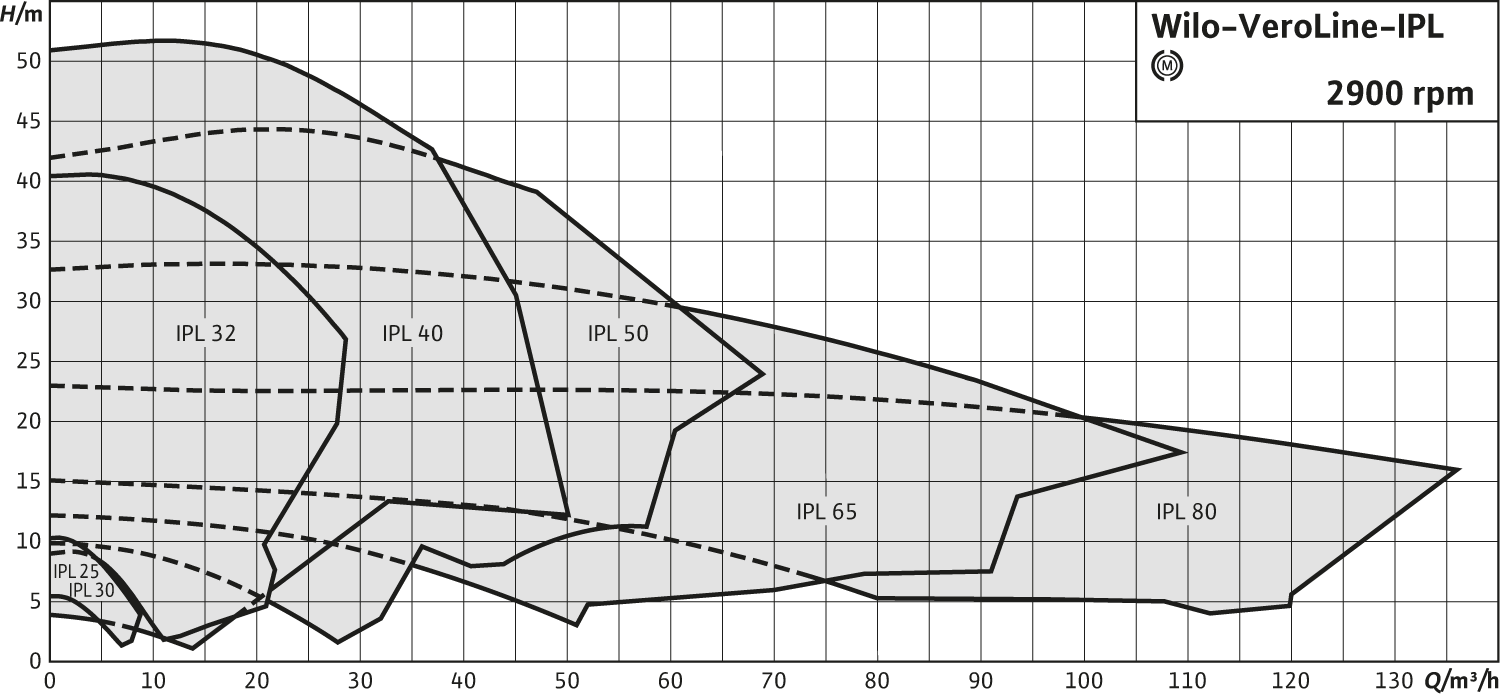

IPL 40/115-0,55/2

Your advantages

- High standard of corrosion protection thanks to cataphoretic coating

- Standard condensate drainage holes in the motor housings and lanterns

- Series design: motor with one-piece shaft

- Version N: Standard motor V1 with stainless steel plug shaft

- Bidirectional, force-flushed mechanical seal

Glanded pump in in-line design with screwed connection or flange connection.

Application

Pumping of heating water (acc. to VDI 2035), cold water and water/glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Scope of delivery

- Pump

- Installation and operating instructions

- Permissible temperature range -20 °C to +120 °C

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP 55

- Nominal diameter Rp 1 to DN 100

- Max. operating pressure 10 bar (special version: 16 bar)

- Pump housing and lantern: EN-GJL-250

- Impeller: PPO fibreglass-reinforced EN-GJL-200 (depending on pump type)

- Shaft: 1.4021

- Mechanical seal: AQEGG; other mechanical seals on request

Single-stage, low-pressure centrifugal pump in in-line design with:

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Motor with one-piece shaft

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 49 mm.

- Outer diameter: 85 mm.

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Terminals for external, potential-free activation/deactivation

- Connection terminal strip

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Fault signal light

- Terminals for external, potential-free activation/deactivation

- Potential-free contacts for external run signal (SBM) and fault signal (SSM)

- Connection terminal strip

- Switchgear SK 622N

- 4 threaded cable connections M20

- Installation and operating instructions

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.